Sales: newhart-phol@comcast.net

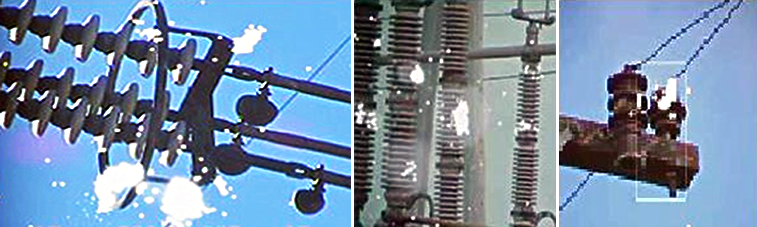

Corona Detection

The Costly Issues at Hand

The cost of maintenance in operating overhead transmission systems is one of the largest expense items. Early detection of faulty power system components before problems occur will reduce maintenance costs and improve dependability. Inspecting equipment while in-service can be extremely challenging – especially when those components are positioned in high locales or difficult terrain. One way to detect potentially faulty components is thru corona identification. Corona is a luminous release which occurs due to air ionization.

Detection Services:

Corona Camera Survey / Analysis – Corona discharge emits radiation in the UV spectral range – invisible to you and me. Our camera uses two channels: UV and visible. The images are then overlaid to make fault identification.While IR cameras are complimentary to corona cameras in providing an overall status, Corona does not generate heat so IR cannot pick it up.Corona imaging will reveal corona in early stages of insulation thereby reducing your Maintenance Cost. You will avoid unplanned costs, extend your assets life time, increase productivity and reduce labor time, lower the risk of in-service failures, increase overall safety, and will shorten over-all project time.

Indicators of Underlying Problems

- Possible Faults

- Sealing defects

- Shorted bells

- Gap discharge

- Loose Hardware

- Contamination

- Corrosion or erosion

- Bad ground connections

Possible Effects of Corona

- Degradation of polymer (NCI) insulators

- Ceramic Insulator defects

- Physical damage to component

- Cracks between the metal cap and pin of porcelain insulators

- Wood pole fires

- Audio noise

© New-Hart Services | All Rights Reserved